Production

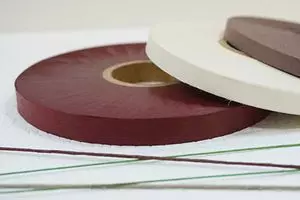

Sample and Order Confirmation

- Offer samples according to clients' needs and specifications.

- Hand-made sampling or production line sampling depending on the products.

- Confirm the details of the order, such as product specifications, payment conditions, delivery conditions, etc.

Pre-Production Meeting

- Inform the related divisions of the production notifications of each order.

- Develop the production schedule and plan.

- Make a tracking item list for further production process tracking.

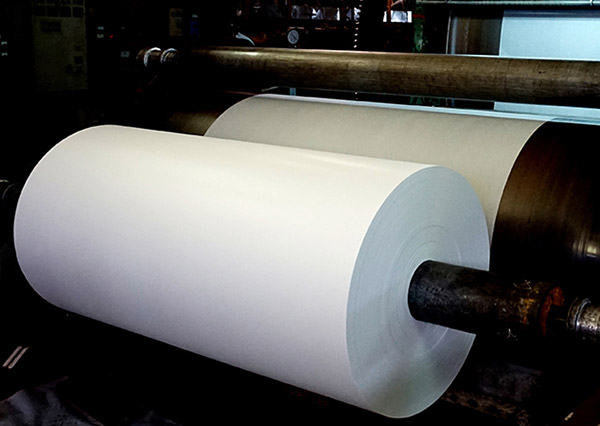

Mass Production and Quality Inspection

- The quality control section sets quality test standards based on the order for each division's assessment.

- Each division and operator conducts a voluntary inspection and records it.

- The quality control section conducts a quality inspection at each production stage according to Puli Paper's Quality Inspection Regulations, eliminates defective products, and makes adjustments in a timely manner.

- The quality control section performs a final inspection after production, and passing products will proceed to the packaging section.

Packaging

- Check products before packaging, including color, quantity, and size.

- After ensuring that the inner packaging is correct, recheck the quantity, and box the products. Load the products onto pallets if necessary.

- Perform the final inspection after the product is packaged, including the number of boxes and whether the outer packaging is complete and properly fixed.

- Make an anti-terrorist inspection before delivery.

Shipping

- Air Shipment: Export from Taipei Airport, Taiwan

- Sea Shipment: Export from any sea port of Taiwan, Keelung, Taichung or Kaohsiung

- Express Delivery: UPS, DHL, FedEx, EMS, etc.

English

English